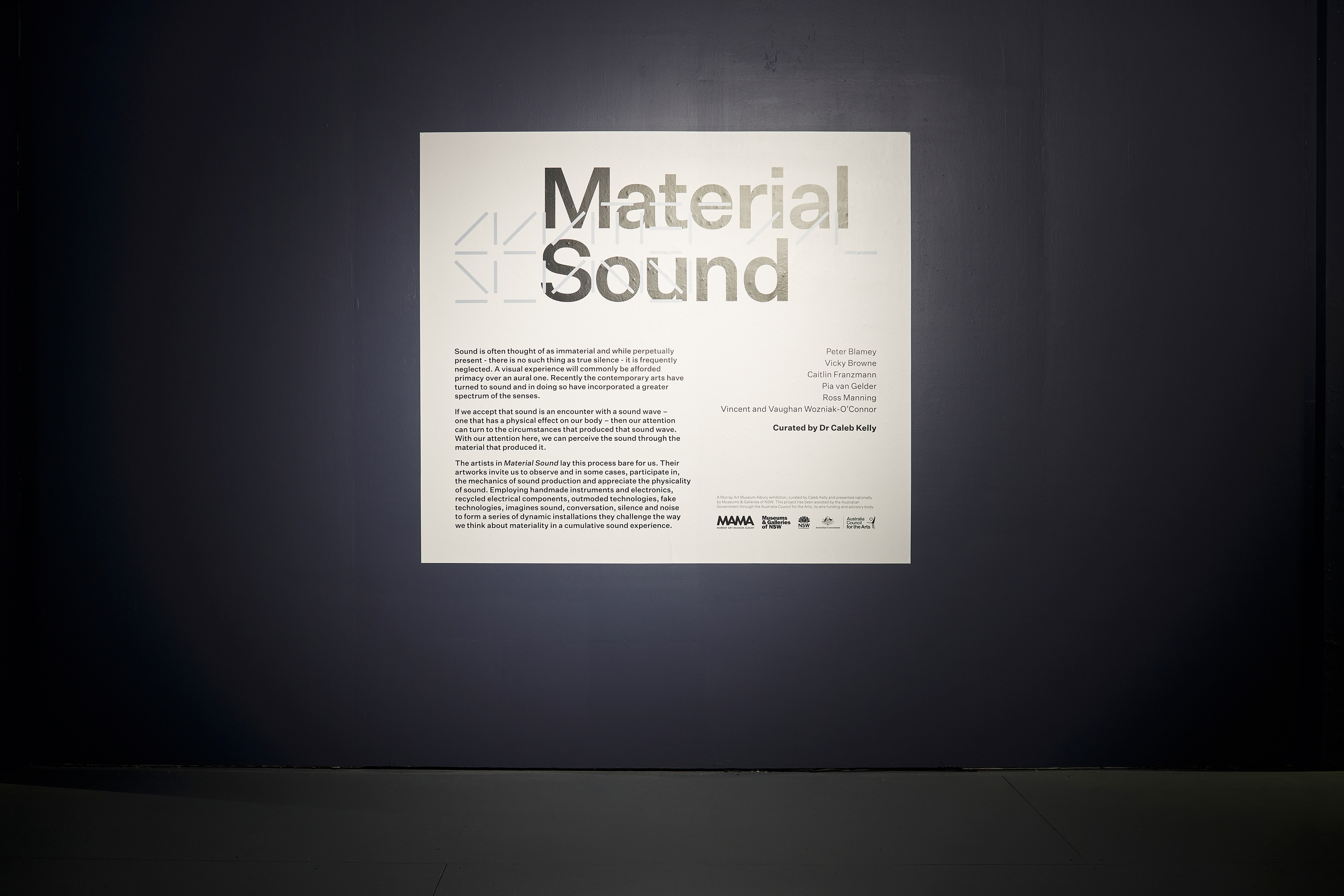

Vaughan and Vincent Wozniak-O'Connor. 'Radiata Studies', installation view at Plimsoll Gallery, Tasmania. As part of 'Material Sound', curated by Caleb Kelly.

Radiata Studies was commissioned for the national touring exhibition ‘Material Sound’, which surveys the work of Australian artists who engage with materiality in sound and installation art. In 2020, I was approached by curator Caleb Kelly who was interested in commissioning a new collaborative work, which iterated from my 2015 collaborative artwork 'Millionth Acre'

'Radiata Studies' (installation view). Radiata pine, laser-cut steel, electronics. Plimsoll Gallery, Hobart, 2021. Dimensions variable.

'Radiata Studies' (detail). Radiata pine, laser-cut steel. Plimsoll Gallery, Hobart, 2021. Dimensions variable.

'Radiata Studies' (detail). Radiata pine, laser-cut steel. Plimsoll Gallery, Hobart, 2021. Dimensions variable.

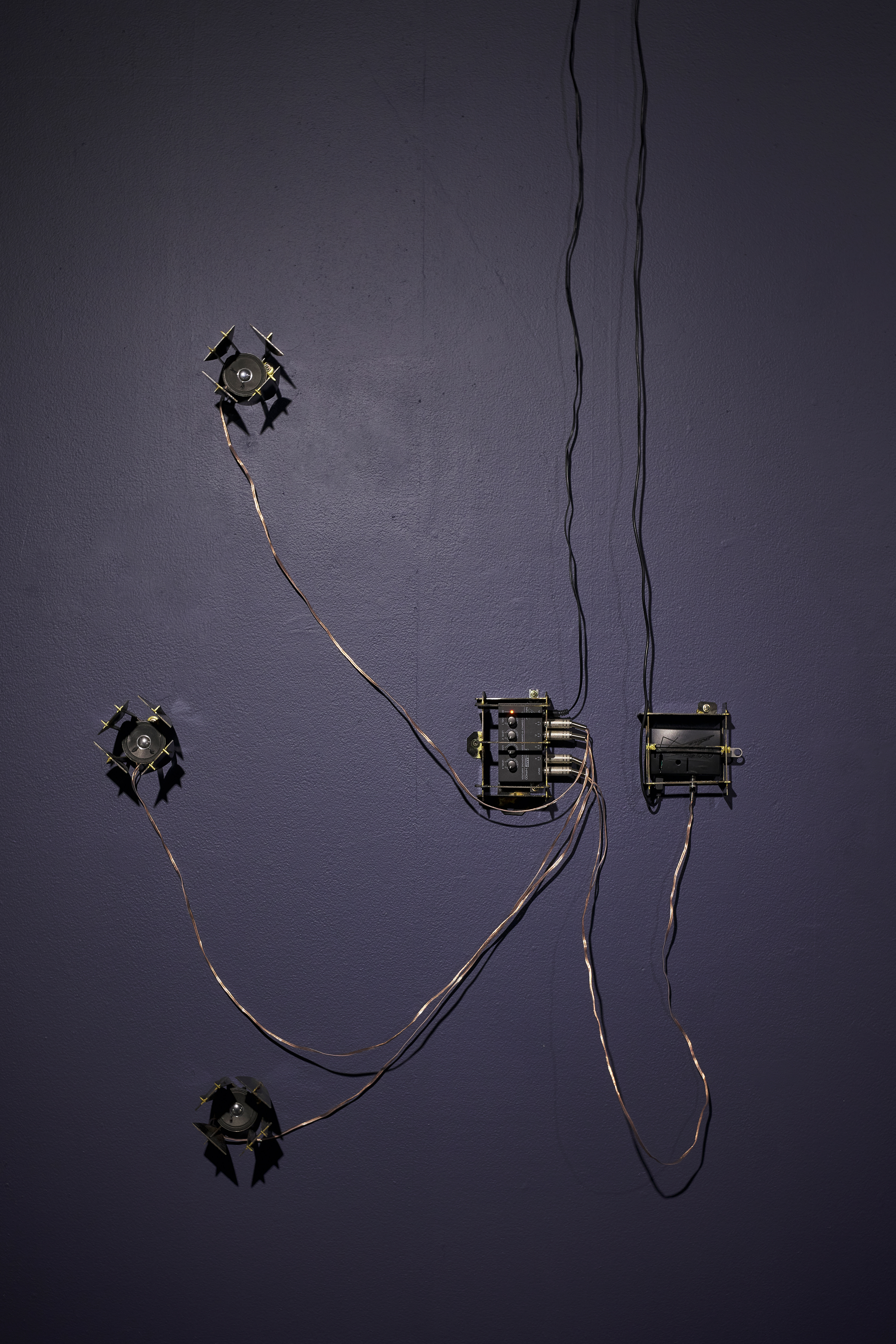

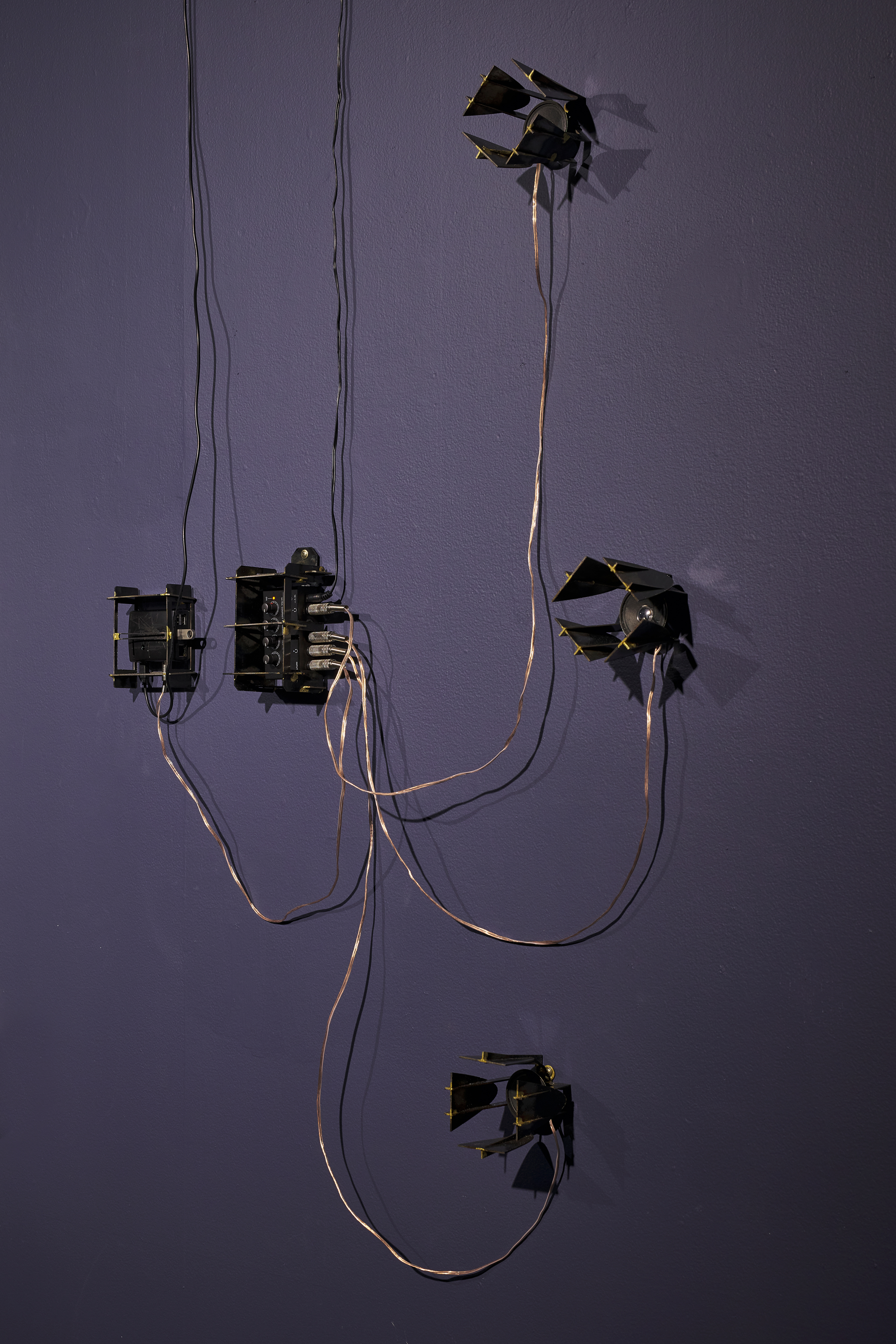

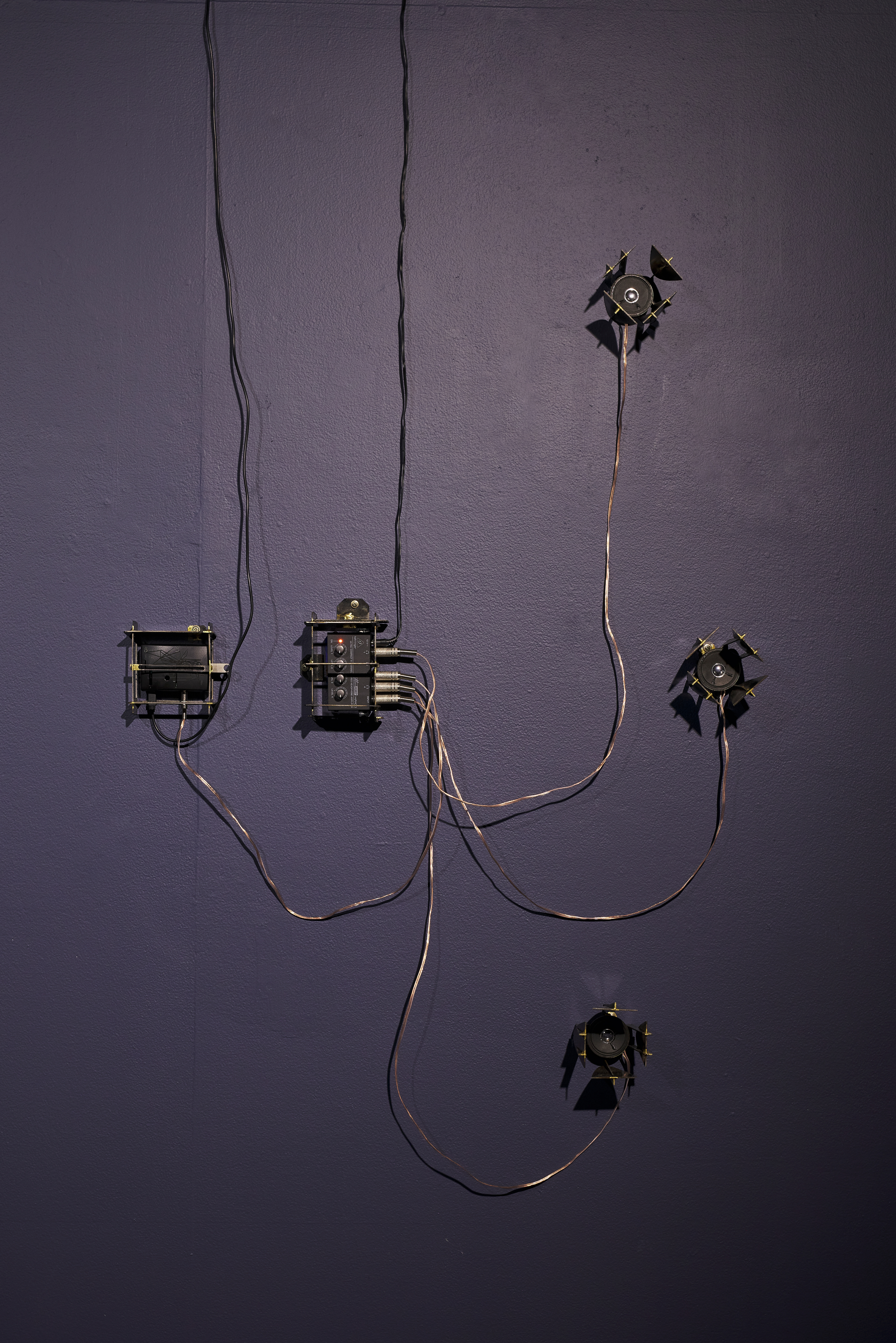

'Radiata Studies' (detail). Custom electronics, laser-cut steel. Plimsoll Gallery, Hobart, 2021. Dimensions variable.

'Radiata Studies' (detail). Custom electronics, laser-cut steel. Plimsoll Gallery, Hobart, 2021.Dimensions variable.

'Radiata Studies' (detail). Custom electronics, laser-cut steel. Plimsoll Gallery, Hobart, 2021.Dimensions variable.

'Radiata Studies' (detail). Radiata pine, laser-cut steel. Plimsoll Gallery, Hobart, 2021. Dimensions variable.

'Radiata Studies' (installation view). Radiata pine, laser-cut steel, electronics. Plimsoll Gallery, Hobart, 2021. Dimensions variable.

Field recording from Millionth Acre, Hampton State Forest

This is a preview of the field recording which plays in 'Radiata Studies'. This recording is of the wind and branches movements of radiata pine on Millionth Acre, in Hampton State Forest, New South Wales. This aspect of the artwork is the contribution of my brother, Vincent, whose research and practice explores field recording which are tranductive, or 'siliviphonic' in nature. That is, this recording taken through the timber of a pine tree. For further details on this process, click here

Practice-based research process:

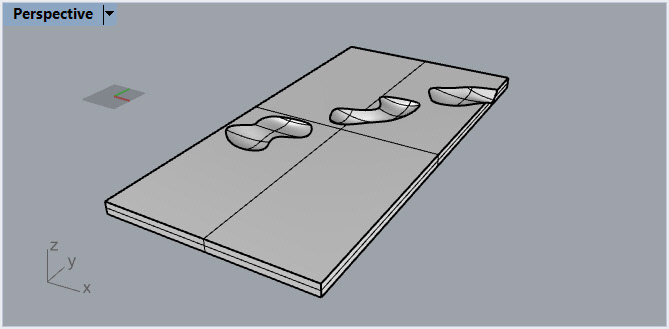

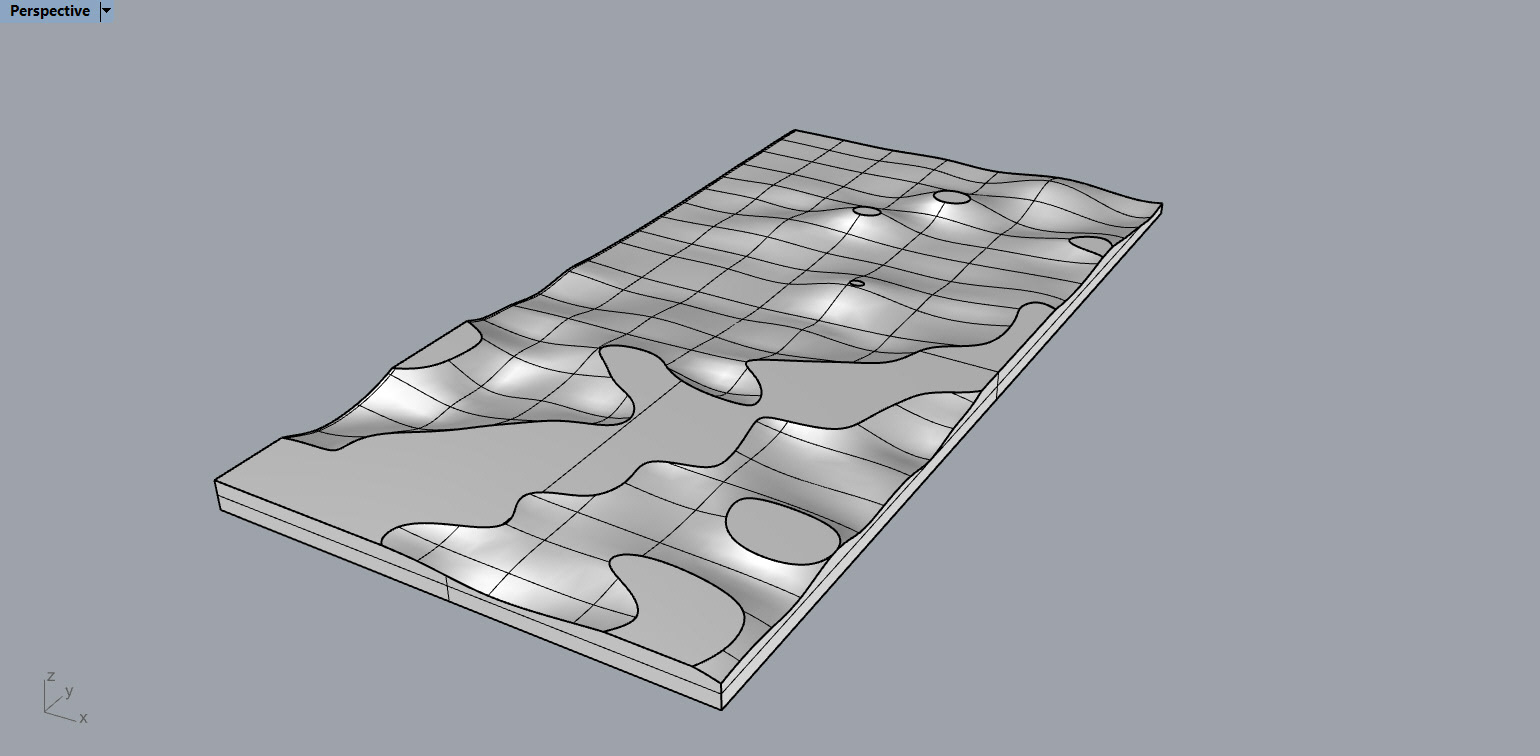

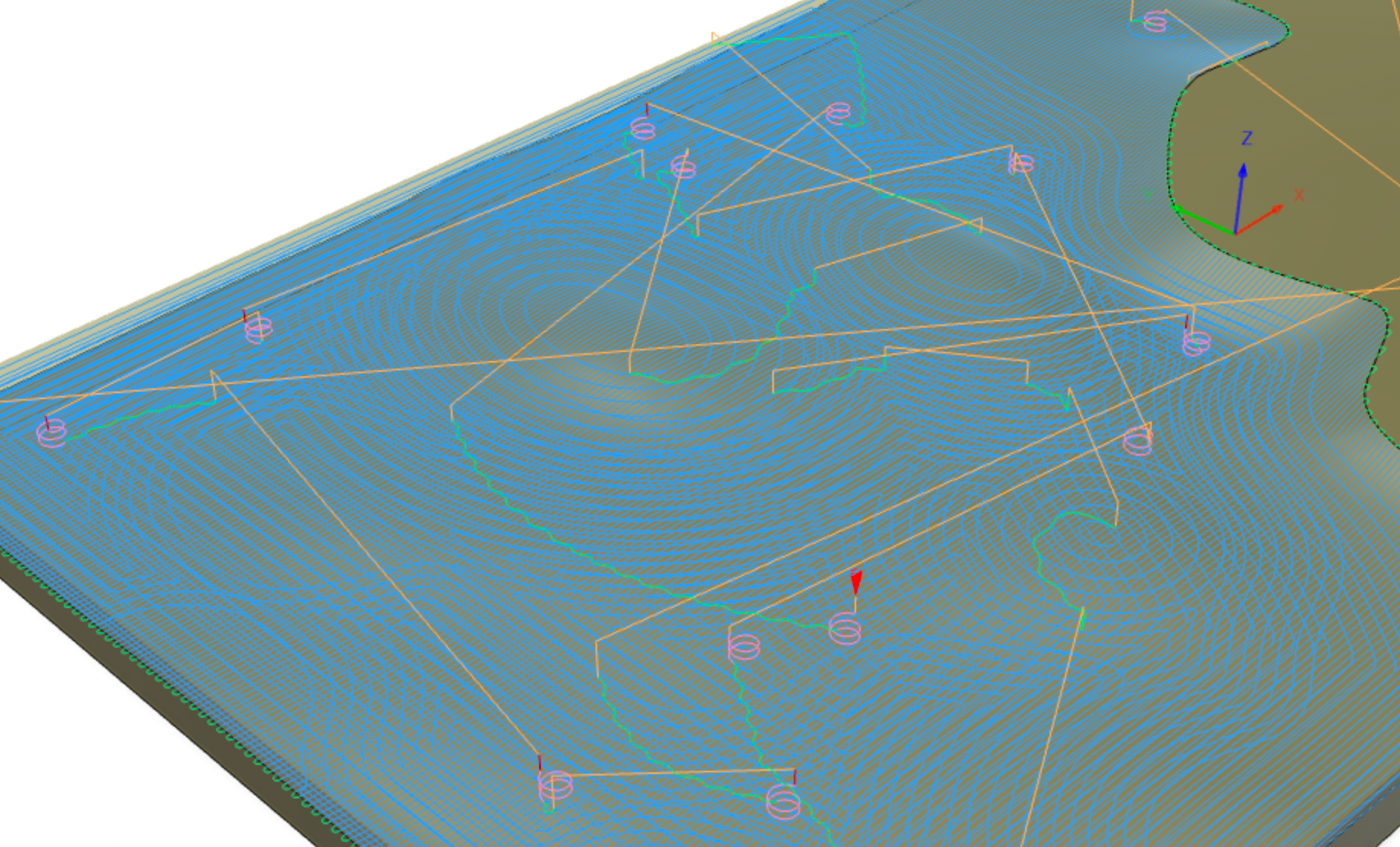

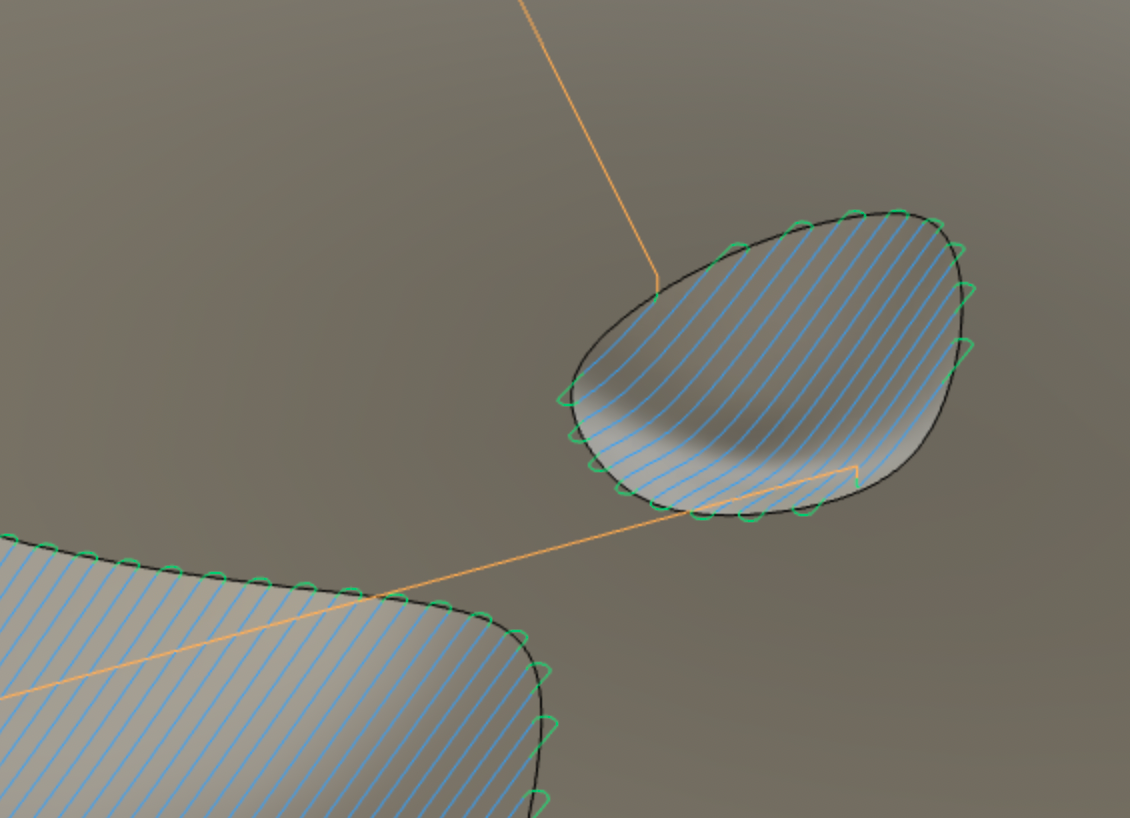

3D models from terrain data (Rhino)

Above are work-in-progress Rhino screenshots, showing the 3D terrain from Millionth Acre, New South Wales, as translated onto panels for CNC routing. The geospatial data used in this artwork comes from the JAXA ALOS digital elevation map (DEM) dataset. In this dataset, high-resolution greyscale imagery is used to recreate 3D terrain data, wherein lower areas of landmass appear in darker shades. More information on the JAXA ALOS dataset can be found here

To create 3D models from this data, I used the 'Heightfield' command in Rhino, which is a common approach for recreating terrain for architectural site maps and models. From here, the Boolean intersect command was used to subtract the terrain topography from shapes which simulated the timber panels to be used in the artwork.

To create 3D models from this data, I used the 'Heightfield' command in Rhino, which is a common approach for recreating terrain for architectural site maps and models. From here, the Boolean intersect command was used to subtract the terrain topography from shapes which simulated the timber panels to be used in the artwork.

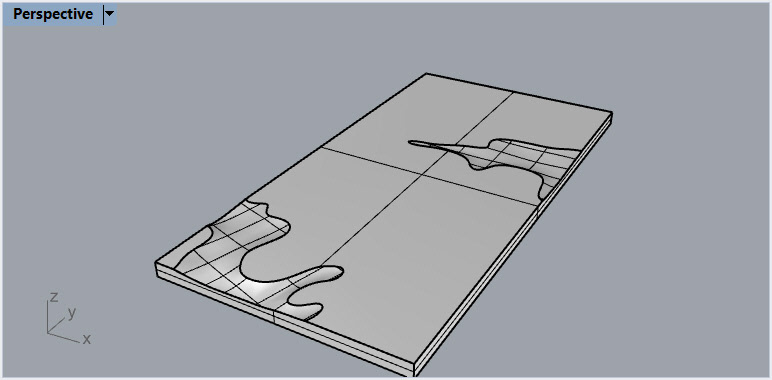

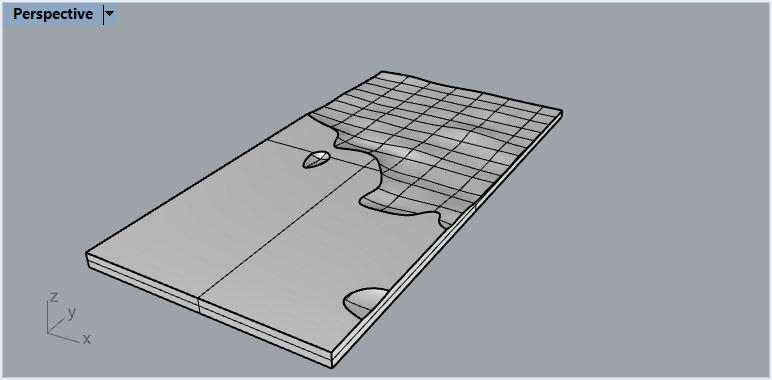

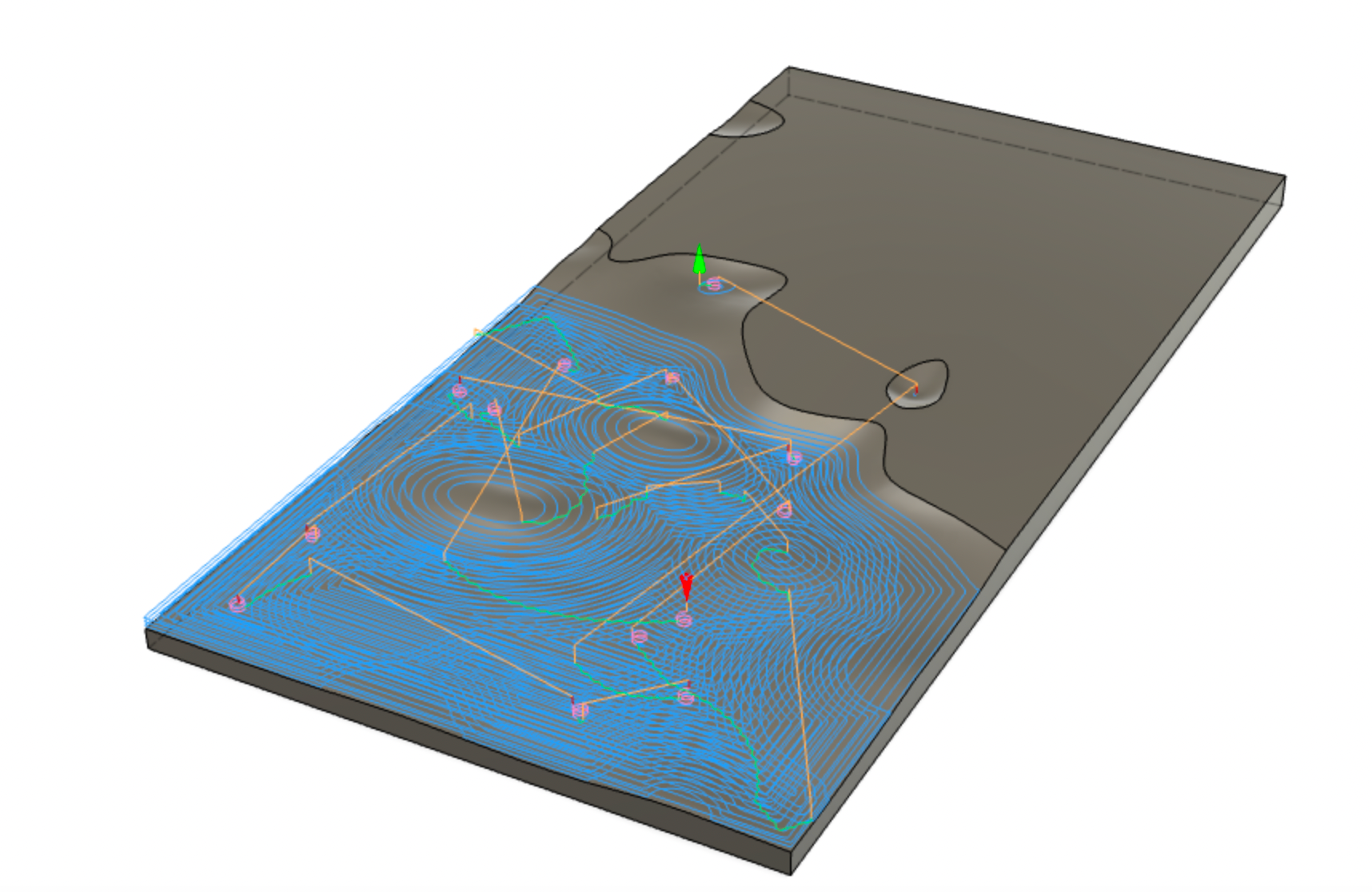

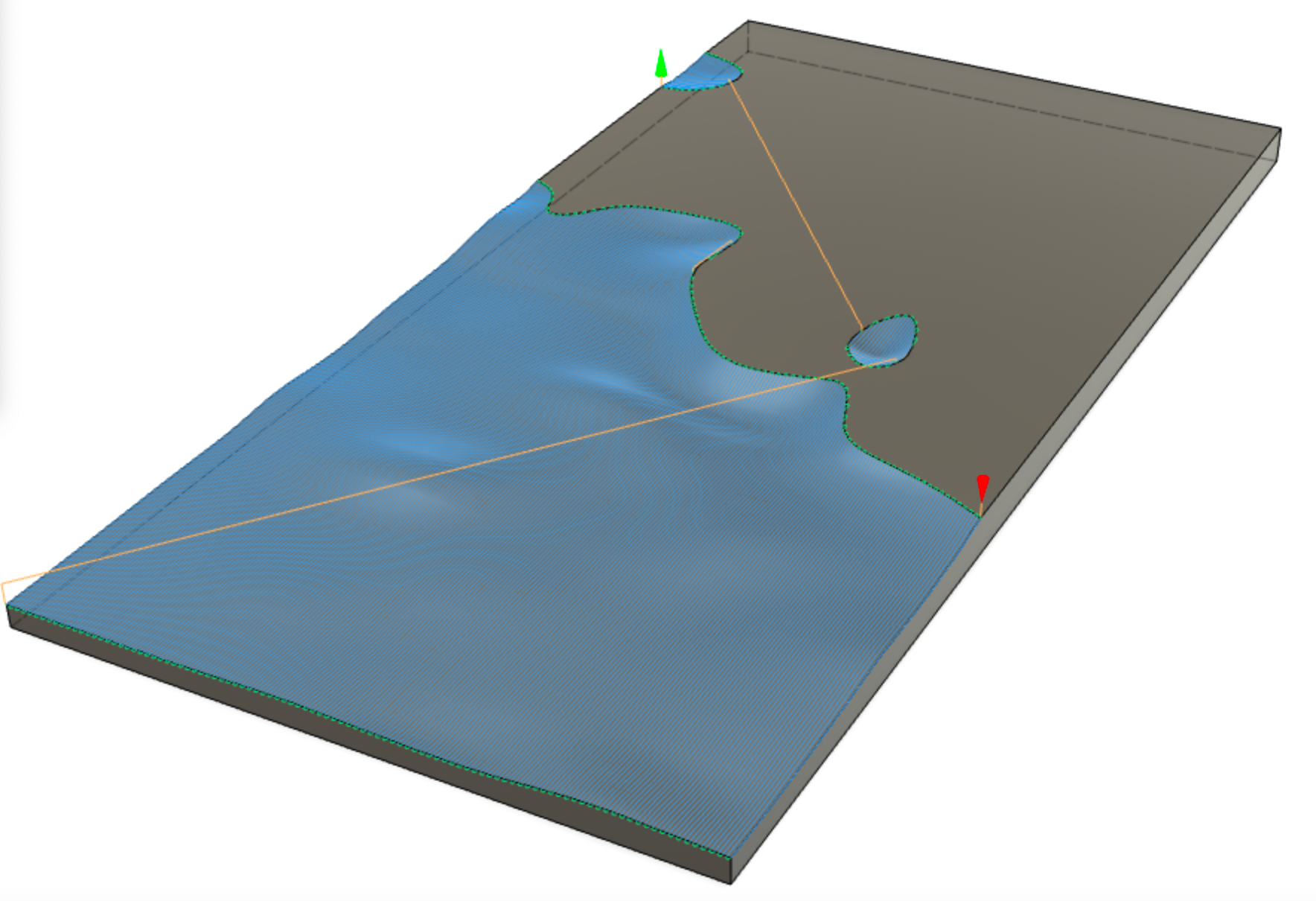

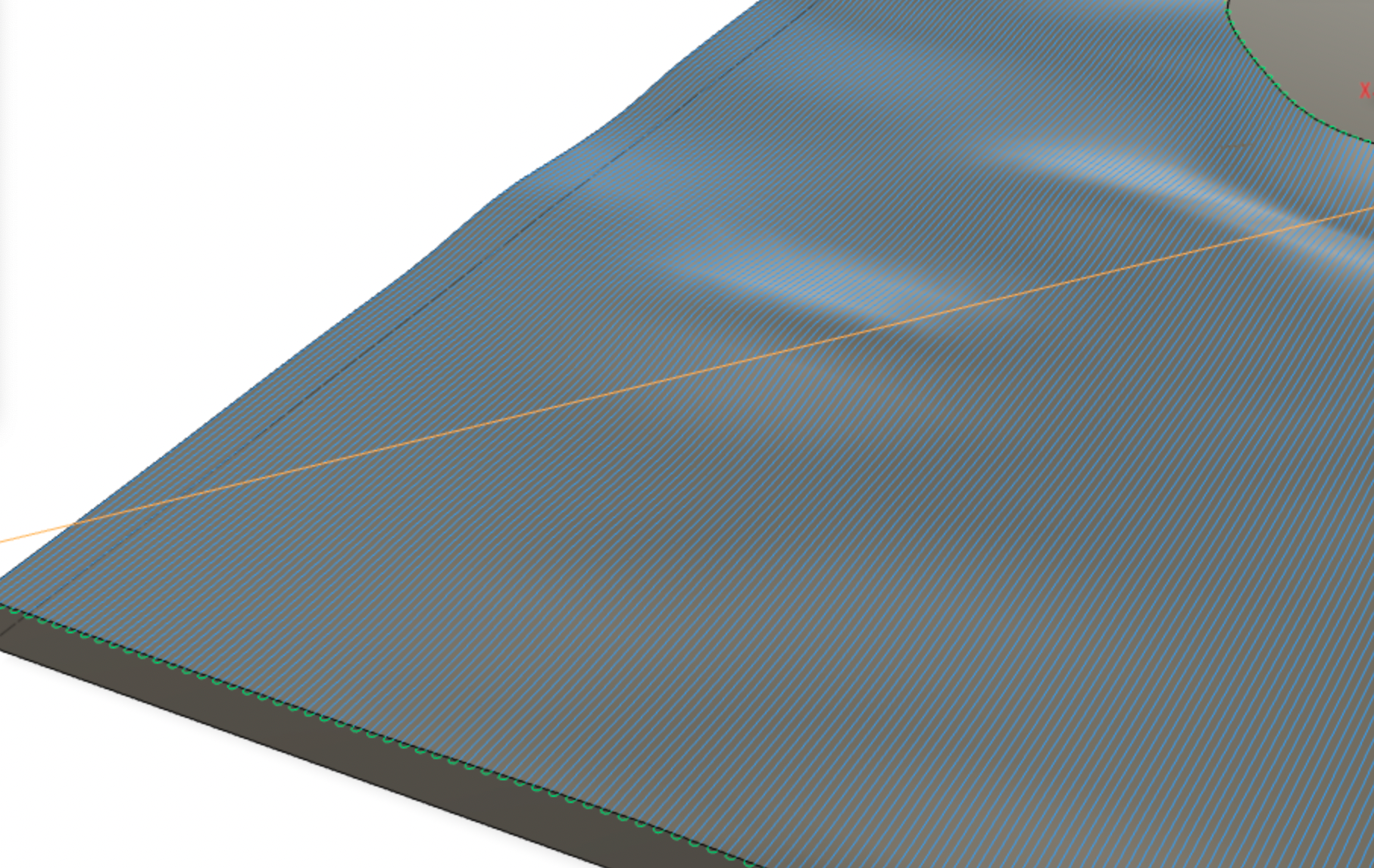

Tool paths for CNC routing

Fusion360 screenshot showing overlay of tool path simulations for both adaptive and parallel clearing operations. Blue lines show simulation of tool movement while cutting, while orange and green lines display movement tool movement between shapes.

Fusion 360 screenshot showing detail of adaptive clearing tool pathway. This clearing operation removes the main contours from the material using a roughing bit.

Fusion 360 screenshot showing detail of parallel tool paths. The parallel clearing operation follows a series of parallel lines and as such, is slower and more arduous than the initial rough clearing stage

Detail showing the dense parallel lines being used to clear material to approximate terrain data

Detail showing a small undulation in the panel surface being carved used the parallel tool path

Above are work in progress screenshots showing the tool paths used to CNC route the plywood panels in 'Radiata Studies'. A combination of adaptive clearing and parallel tool paths were used to carve terrain data into the plywood panels. The distinctive surface of 'Radiata Studies' comes from the interplay between the layers of lamination of the plywood being exposed by the vertical tool movement of a 6mm ball-end upcut router bit.

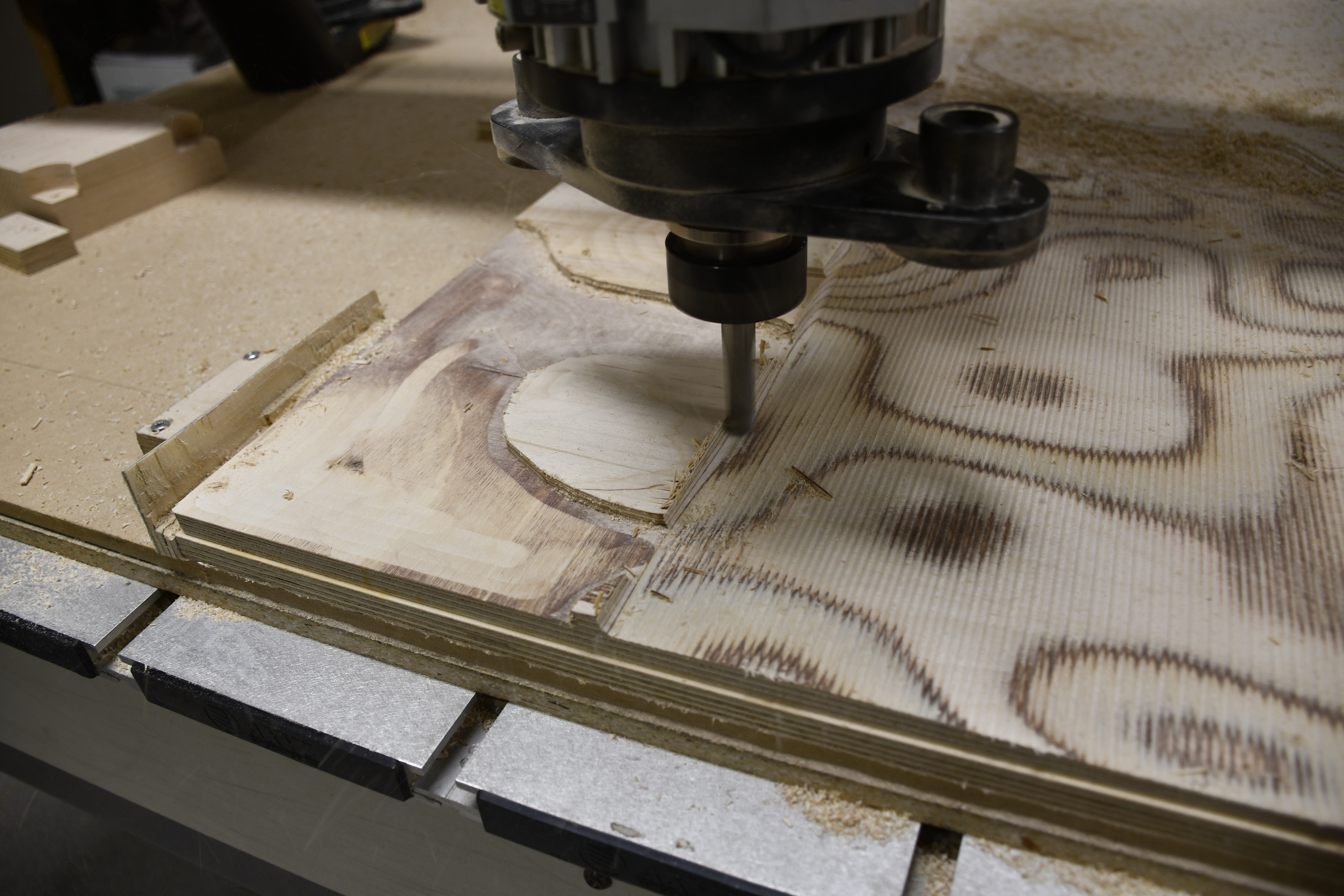

Fabrication process: CNC machining (Multicam) and laser-cutting (KERN)

High gantry Multicam CNC in the Advanced Manufacturing Lab, UNSW Sydney. This machine was used extensively to produce artworks in the later part of my research candidacy

CNC router performing adaptive clearing operations on 'Radiata Studies' panel;

Work in progress depicting contrasting surface finish between adaptive clearing and parallel tool path operations. The dark sections in this work are exposed adhesive between layers of radiata pine veneer.

Detail of ball-end mill removing stock toward the end of the machining process.

Completed panel as fixtured to the bed of the Multicam CNC router.

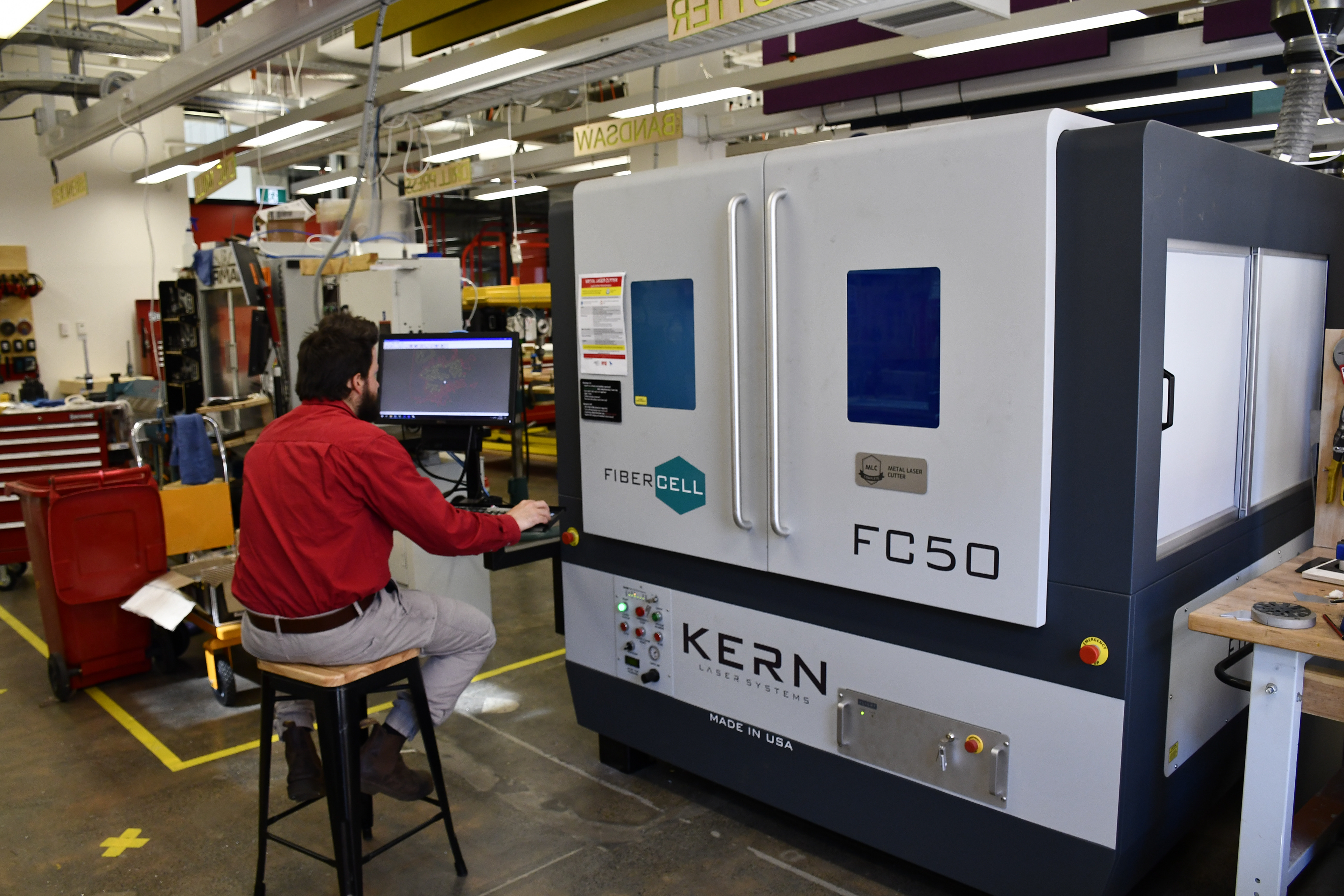

KERN FC50 industrial lasercutter. This machine is in the James N. Kirby makerspace at UNSW Sydney and was used to lasercut self-tracking GPS trails for the artwork 'Radiata Studies'

Panel from 'Millionth Acre' (2015) after being lasercut for reuse in the artwork 'Radiata Studies'

Detail of lasercut steel surface of artwork. In some sections, small shapes fell out of the artwork, while in others metal accidentally melted back onto the panel after being cut

Above are work in progress images of the fabrication of 'Radiata Studies'. CNC routing of terrain data was done on a Multicam router at the Advanced Fabrication Lab at UNSW Sydney. Steel lasercutting was done on a KERN FC50 industrial lasercutter at James N. Kirby Makerspace at UNSW Sydney. The steel panel used in this artwork was taken from artwork 'Millionth Acre' (2015), which depicted the waveform of a field recording taken from Millionth Acre pine plantation in Central Western New South Wales. This work was originally commissioned as a reiteration of the collaborative artwork 'Millionth Acre'. The reuse of this panel serves as a material link to the original work, but is otherwise opaque to the viewer.

'Radiata Studies' CNC Machining on Multicam CNC

Documentation of CNC routing being done at the Advanced Manufacturing Lab, UNSW Sydney. Manual extraction/vaccuuming was required to produce this artwork, to avoid the collett /spindle colliding with the plywood stock. While digital fabrication is commonly understood as predetermined or automatic, such manual interventions are common by machine operators and are not always predicted in software simulations.